MIL-DTL-13791G

shall be determined by visual examination for defects.

4.10.3 Voltage output. To determine conformance to 3.5.1, the distributor assembly shall be

electrically connected and mechanically mounted in an apparatus to simulate operation. Each secondary

lead shall be shunted through load capacitance of 150 10 picofarads (pF). One secondary lead shall be

connected to a peak voltage measuring device. Remaining secondary leads shall be connected to spark

gap as specified in MIL-DTL 13791/16. Spark gap shall be 3 mm. The distributor assembly shall be

operated at each input speed and voltage specified in table II. The distributor assembly shall be operated

for 3 minutes before taking each measurement. Measurement of output voltage shall be taken at each

lead, and recorded. The lowest voltage measured at any secondary lead shall be considered voltage

output at that input speed and voltage. Thereafter, total capacitance of each secondary lead shall be

adjusted to 150 10 pF with resistance ungrounded. With 250,000 ohms 25,000 ohms shunted across

the secondary lead, and with 30 V dc and 1800 rpm input, the output voltage shall be measured and

recorded at each secondary lead. The lowest reading shall be considered voltage output for the

distributor assembly. Subsequently, the distributor cap shall be removed and examined for interference

with rotor. Satisfactory distributors, or repair parts, shall be reassembled and the test sequence resumed.

4.10.3.1 Low input voltage. To determine conformance to 3.5.1.1, a class 2 distributor, assembled,

mounted and operating, shall be subjected to correctly polarized input voltages between zero and

18 V dc.

4.10.3.2 High input voltage. To determine conformance to 3.5.1.2, a class 2 distributor, assembled,

mounted and operating, shall be subjected to correctly polarized input voltages between 30 and 40 V dc.

shall be operated through range of speeds, and timing of spark shall be measured and recorded for

comparison with requirements.

4.10.5 Dielectric strength. To determine conformance to 3.5.3, each output lead of the distributor

shall be connected to the spark gap, as specified in MIL-DTL-13791/16, set at 8 mm. No additional load

shall be imposed on distributor. Input voltage shall be 32 0.5 V dc. The distributor shall be operated at

200 rpm for 2 minutes. Two output leads adjacent to the coil shall then be connected to ground,

remaining leads to 8 mm gaps, and tests repeated for 2 minutes. The distributor shall then be examined

for evidence of breakdown of insulation materials.

4.10.6 Endurance. To determine conformance to 3.5.4, the distributor shall be electrically connected

and mechanically mounted, as specified in 4.7.1, in ambient air temperature of 160 + 10ºF. Spark gap, as

specified in MIL-DTL 13791/16, shall be set at 3 mm and loaded with a capacitance of 150 10 pF. With

input of 28.5 V dc 0.5 V dc, the assembly shall be operated continuously through 300 cycles for class 1,

or 750 cycles for class 2 of the following four phases as specified in table XI (phases I - IV equal one

cycle):

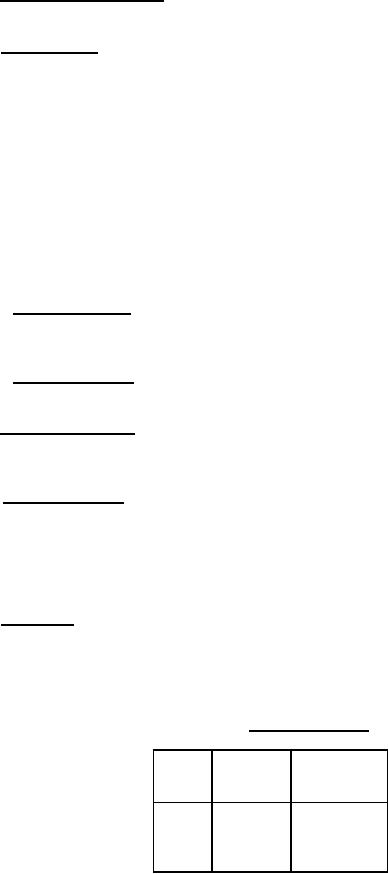

TABLE XI. Endurance cycles.

Distributor

Time

Phase

Shaft speed

(minutes)

(rpm)

I

30

300

II

30

800

III

30

1500

IV

30

2000

After each 100 hours (50 cycles) of operation as specified above, the distributor shall undergo the

following:

a. Observe sparking regularity for 10 minutes at each specified speed.

b. Observe output voltage at 300 rpm.

14

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business