MIL-DTL-13791G

3.3.1 Slash sheet reference specification.

Army drawing number

Slash sheet reference

7355734

MIL-DTL-13791/1

7762671

MIL-DTL-13791/2

7762685

MIL-DTL-13791/3

12259526

MIL-DTL-13791/4

7353276

MIL-DTL-13791/5

7355596

MIL-DTL-13791/6

7358569

MIL-DTL-13791/7

7374377

MIL-DTL-13791/8

5701239

MIL-DTL-13791/10

7348578

MIL-DTL-13791/11

7374880

MIL-DTL-13791/12

7374883

MIL-DTL-13791/13

7375373

MIL-DTL-13791/14

7539588

MIL-DTL-13791/15

7727531

MIL-DTL-13791/16

8722526

MIL-DTL-13791/17

11640924

MIL-DTL-13791/19

11663066

MIL-DTL-13791/20

10863489

MIL-DTL-13791/21

NASM35206

MIL-DTL-13791/22

3.3.2 Cadmium is not recommended. It is recommended that the use of carbon steel material with

cadmium plating be used only when the other materials and plating finishes specified in this document

cannot meet performance requirements (see table ll).

3.3.2.1 Protected plating. Proper protected coating type plating shall be in accordance with SAE-

AMS-C-81562, type II, class 3 or SAE-AMS-QQ-P-416, type II class 2. Fluid passages, other openings,

and internal threads shall not be subject to the plating thickness requirement and may have bare areas

provided they are protected with a light film of oil.

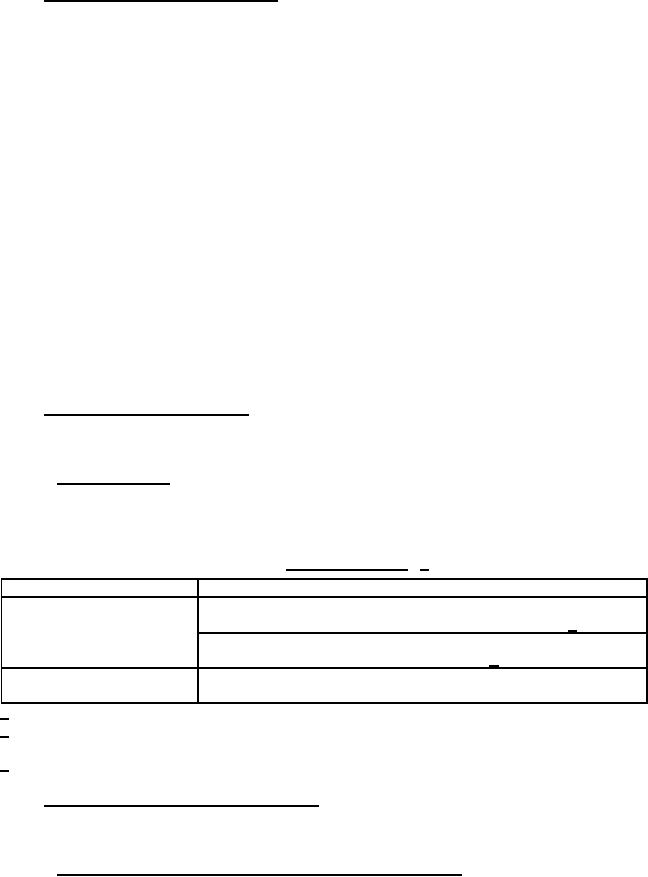

TABLE ll. Material and finish. 1/

Material

Finish

Cadmium plating in accordance with SAE-AMS-C-81562,

type II, class 3 or SAE-AMS-QQ-P-416, type II, class. 2/

Carbon Steel

Zinc plating in accordance with ASTM-B633; type II or III,

Fe/Zn 25, or ASTM-B695, type II, class 5. 3/

No additional finish. Passivation in accordance with

300 series stainless steel

SAE-AMS2700, type 6 or 7.

1/ Must be capable of withstanding 96 hours salt spray.

2/ Not recommended for use where severe abrasion conditions exist. Max service temperature

120°C.

3/ Embitterment test need not be run.

3.3.3 Recycled, virgin, and reclaimed materials. There are no requirements for the exclusive use of

virgin materials. The use of recycled or reclaimed (recovered) materials is acceptable provided that all

other requirements of this specification are met (see 4.10.1 and 6.3.5).

3.3.3.1 Recycled, recovered, or environmentally preferable materials. Recycled, recovered, or

environmentally preferable materials should be used to the maximum extent possible, provided that the

material meets or exceeds the operational and maintenance requirements, and promotes economically

advantageous life cycle costs.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business