MIL-DTL-13791G

3.4 Design and construction. Distributors shall conform to applicable drawings and standards for

type and class (see 1.2). Authorized repair parts will conform to the form and dimensions specified on the

drawings specified in table I (see 3.3.1, 4.10.1, 4.10.2 and 6.2).

3.4.1 Interchangeability. All distributor assemblies and authorized repair parts shall be physically

and functionally interchangeable with all other products of the same part number (see 4.10.1 and 4.10.2).

3.4.2 Housing. Distributor housing shall be so constructed as to be electrically continuous

(see 4.10.2).

3.4.2.1 Coil-to-distributor lead. When specified (see 6.2), provision shall be made to permit

connection to coil-to-distributor lead for testing purposes (see 4.10.1 and 4.10.2).

3.4.3 Timing: initial setting. Timing of distributor shall be accomplished by rotation of the complete

distributor assembly in its mounting (see 4.10.2).

3.4.3.1 Advance and retard. Spark advance mechanism will be centrifugal. The centrifugal spark

advance mechanisms must continuously adjust timing of voltage output at the spark gap in conformance

to the advance curve specified on applicable drawings or military standards (MS) (see 4.10.1 and 4.10.2).

3.4.4 Drive arrangement. Distributor shaft speed will be one-half crankshaft speed. Drive end of the

shaft will be designed so that mating parts will not be assembled 180 degrees (º) out of line (see 4.10.2).

3.4.5 Ventilation. Provision will be made for ventilation as specified on applicable drawing or MS

sheet (see 4.10.1 and 4.10.2).

3.4.6 Lubrication. The breaker cam follower will be designed so that no additional lubrication will be

required when operation time is less than 100 hours. The rotor shaft bearing must be designed so that no

additional lubrication will be required when operation time for class 1 distributor is less than 600 hours

and when operation of class 2 distributor is less than 1500 hours (see 4.10.2).

3.4.7 Threaded parts. Screw threads of the form, number per inch, and class specified on the

applicable drawing or MS sheet must be in accordance with FED-STD-H28/2 (see 4.10.1 and 4.10.2).

3.5 Performance.

3.5.1 Voltage output. The distributor will produce no less than minimum voltage output at each

output terminal under operating conditions specified in table llI. Variation of output voltage from output

terminal to output terminal will be no more than 10 percent (%). When operating, the distributor will

produce no less than 6000 V dc at output terminals. The distributor must then be operated for 3 hours at

300 revolutions per minute (rpm) and 3 hours at 1800 rpm. Thereafter, the distributor cap will be

examined and there will be no evidence of cap and rotor interference (see 4.10.3).

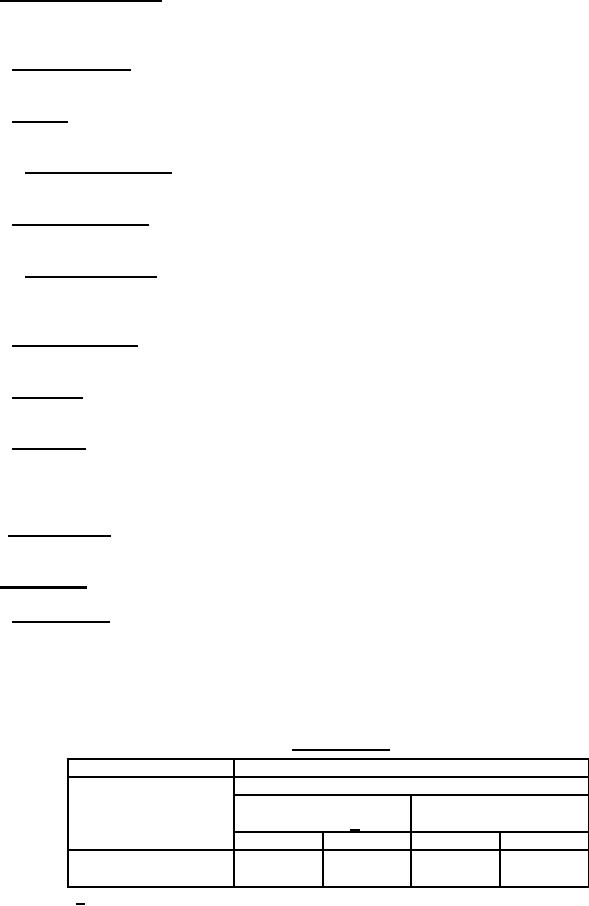

TABLE llI. Voltage output.

Output

Conditions

Voltage output, minimum kilovolts (kV)

Distributor shaft speed Ambient air temperature Ambient air temperature

200 10ºF

77 15ºF 1/

(rpm)

18 V input 30 V input 18 V input 30 V input

300 10

14 kV

17 kV

10 kV

15 kV

1800 25

12 kV

17 kV

10 kV

14 kV

1/ °F = degrees Fahrenheit

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business