MIL-DTL-62548C(AT)

cost effective sampling procedures to verify performance. See the contract for alternatives that

replace verification methods required by this specification (see 6.2).

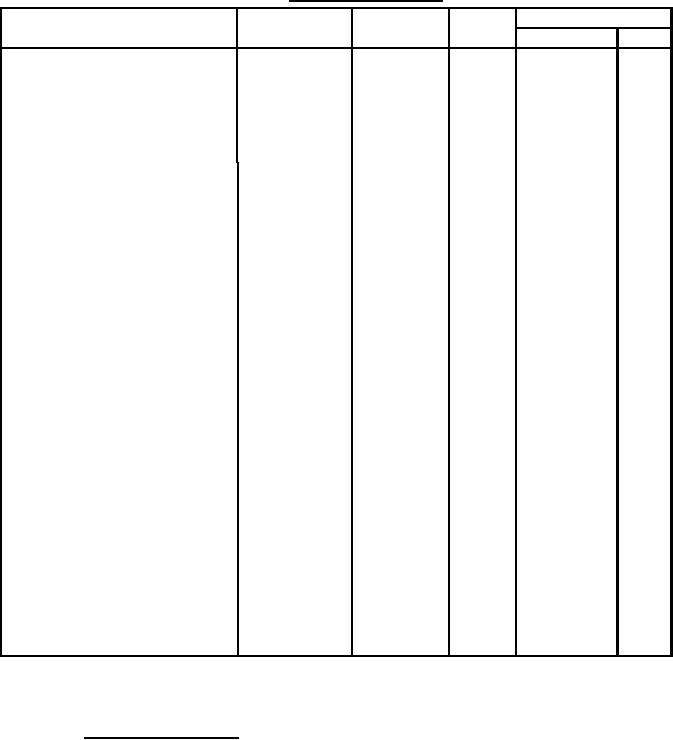

Table I. Verification methods.

First

CI

Title

Requirement

Verification

article

Examination

Test

Design, materials and

manufacturing

3.2 and 3.2.2

4.2.3

X

X

3.3

4.2.4

Operating requirements

Nuclear control

3.3.1

4.2.4.1

X

Insulation resistance

3.3.2

4.2.4.2

X

X

Maximum voltage

3.3.3

4.2.4.3

X

X

Accelerated aging

3.3.4

4.2.4.4

X

Nuclear hardening

3.3.5

4.2.4.5

X

3.4

4.2.5

Interface requirements

Electromagnetic interference

3.4.1

4.2.5.1

X

Support and ownership

3.5

4.2.6

requirements

Identification and marking

3.5.1

4.2.6.1

X

X

Interchangeability

3.5.2

4.2.6.2

X

X

Safety

3.5.3

4.2.6.3

X

X

Operating environment

3.6

4.2.7

requirements

High temperature

3.6.1

4.2.7.1.1

X

Room temperature

3.6.1

4.2.7.1.2

X

Low temperature

3.6.1

4.2.7.1.3

X

Operational altitude range

3.6.2

4.2.7.4

X

Humidity

3.6.3

4.2.7.5

X

Salt spray

3.6.4

4.2.7.6

X

Sand and dust

3.6.5

4.2.7.7

X

Fungus

3.6.6

4.2.7.8

X

Chemical resistance

3.6.7

4.2.7.9

X

Vibration

3.6.8

4.2.7.10

X

Shock

3.6.9

4.2.7.11

X

Gun firing shock

3.6.9.1

4.2.7.11.1

X

Ballistic shock

3.6.9.2

4.2.7.11.2

X

Basic shock

3.6.9.3

4.2.7.11.3

X

Submergence

3.6.10

4.2.7.12

X

4.2.2 Inspection conditions. Unless otherwise specified herein, all inspections shall be

conducted at an atmospheric pressure of approximately 30 inches of mercury and at a

temperature of 70 °F to 80 °F (21 °C to 27 °C) and a relative humidity of 90% or less.

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business