MIL-PRF-62061D

cost effective sampling procedures to verify performance. See the contract for alternatives that

replace verification methods required by this specification.

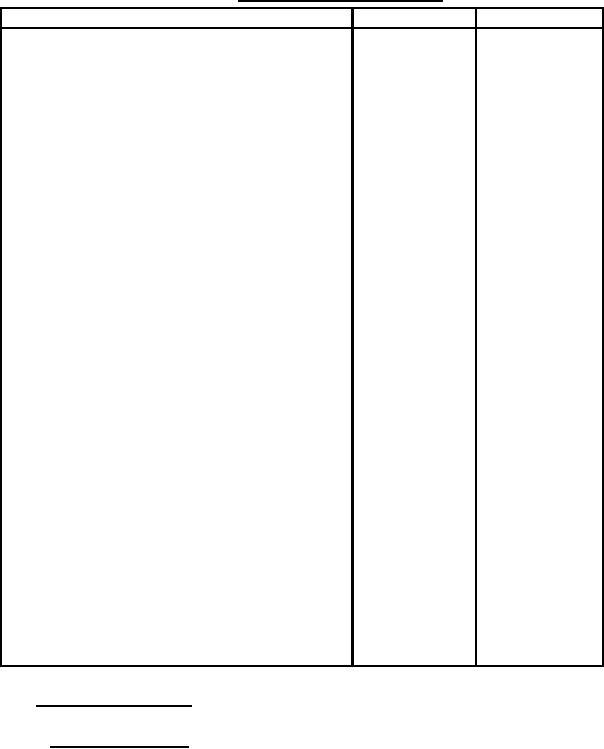

TABLE I. Classification of inspections.

Title

Requirement

Inspection

3.3

4.5

Operating requirements

Polarity

3.3.1

4.5.1

Output

3.3.2

4.5.2

Output, performance checkpoint (heat stabilized)

3.3.2.1

4.5.2.1

Speeds and current

3.3.2.2

4.5.2.2

Interpole voltage

3.3.3

4.5.3 - 4.5.3.2

Compounding

3.3.4

4.5.4

Insulation resistance

3.3.5

4.5.5 - 4.5.5.2

Ripple

3.3.6

4.5.6

Generator flexible drive

3.3.7

4.5.7

Torsional vibration, 100 hours

3.3.7.1

4.5.7.1

Torsional vibration, 15 minutes

3.3.7.2

4.5.7.2

3.4

4.6

Interface requirements

Design interface

3.4.1

4.6.1

Interchangeability

3.4.2

4.6.2

Electromagnetic compatibility

3.4.3

4.6.3

3.5

4.7

Ownership and support requirements

Endurance

3.5.1

4.7.1

Overspeed

3.5.2

4.7.2

Dielectric strength

3.5.3

4.7.3

Surface finish

3.5.4

4.7.4

Safety

3.5.5

4.7.5 - 4.7.5.2

Identification

3.5.6

4.7.6

3.6

4.8

Operating environment requirements

High temperature

3.6.1

4.8.1

Low temperature

3.6.2

4.8.2

Shock resistance

3.6.3

4.8.3

Vibration resistance

3.6.4

4.8.4

Fungus resistance

3.6.5

4.8.5

Corrosion resistance

3.6.6

4.8.6

Sand and dust

3.6.7

4.8.7

4.4 Inspection conditions.

4.4.1 Atmospheric limits. Unless otherwise specified (see 6.2), all inspections shall be

conducted under the following conditions:

a. Air temperature 77 ±15 °F

b. Barometric pressure 725 (+50,-75) millimeters (mm) mercury

c. Relative humidity 50 ±30 percent (%)

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business