MIL-PRF-46795H

4.4.1 Sampling. Sampling plan for an inspection lot shall be as specified in the contract

or order (see 6.2).

4.4.2 Examinations. Generating system and repair parts, shall be examined for the

defects in table II. Any redesign or modification of the contractor s standard product to comply

with specified requirements shall receive particular attention for adequacy and suitability. This

element of inspection shall encompass all visual examinations and dimensional measurements.

Noncompliance with any specified requirements or presence of one or more defects preventing or

lessening maximum efficiency shall constitute cause for rejection.

4.4.3 100 percent (%) inspection. All generating systems and repair parts, of one type or

part number, from an identifiable production period, from one manufacturer, shall be tested in

the order listed in accordance with table III, stabilized frame temperature will not be required.

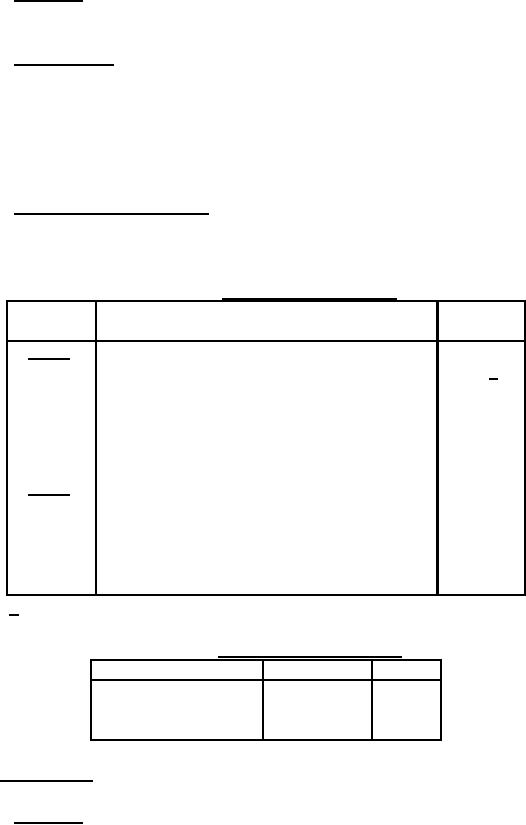

TABLE II. Classification of defects.

Method of

Category

Defect

inspection

Major:

SIE 1/

101

Dimensions affecting interchangeability not

within tolerance (see 3.3 & 3.3.1).

SIE

102

Improper polarity (see 3.3.2).

Visual &

103

If safety conditions are not as specified (see

Functional

3.7).

Minor:

SIE

201

Dimensions not affecting interchangeability not

Visual

202

within tolerance (see 3.3 & 3.3.1).

Visual

203

Improper finish (see 3.5).

Improper marking (see 3.6).

1/ SIE = Standard Inspection Equipment.

TABLE III. Conformance inspections.

Title

Requirement

Test

Rated output

3.4.3

4.9.1.1

Voltage regulation

3.4.2.2

4.8.2.1

Non-operating current

3.4.3.1

4.9.2

4.5 Control tests.

4.5.1 Sampling. Control test samples shall be selected from production lot which has

passed conformance examination as specified in 4.4.2 and acceptance tests as specified in 4.4.3.

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business